Contact us for price

70Kg Halter LoadAssistant Universal BIG 70

or

Call +353 838108745

Description

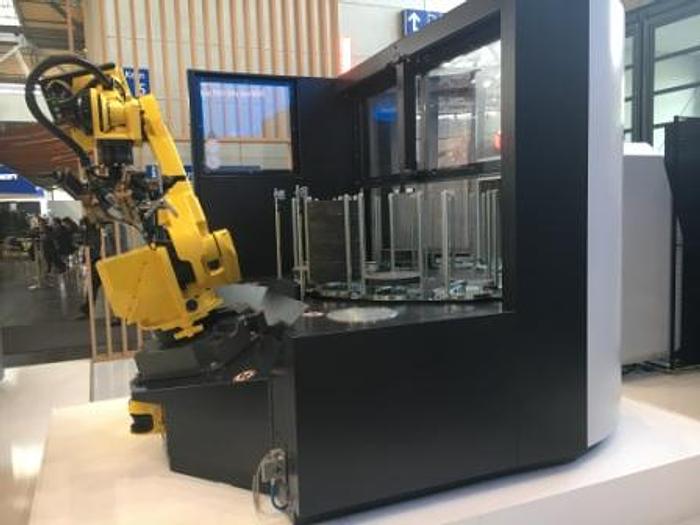

Halter LoadAssistant Universal BIG 70 The HALTER LoadAssistant® is a robotic system for automatic loading of your CNC machine. The CNC robot can be connected to any new or existing CNC lathe or milling machine and easily moved from one machine to another. Complete plug-and-play solution for each brand of CNC machine. Set-up time takes less than 5 minutes. No experience with robotics is required. Easily moved from one CNC machine to another. Reliable technology. Weight Capacity: 70KG Designed for Turning Machines & Milling Machines

Specifications

| Manufacturer | Halter CNC Automation |

| Model | LoadAssistant Universal BIG 70 Robotic Loading System |

| Condition | New |

| Control | Halter SmartControl |

| Standard robot-machine interface for every CNC-machine | Yes |

| Max. number of CNC-machines to connect with | 4 |

| Touch Screen Size | 21" |

| Intuitive and graphical programming in 12 steps | Yes |

| Robot | Fanuc 6 Axis Robot |

| No. of controlled axes | 6 |

| Gripper | 2 or 3 Finger Gripper |

| Other Grippers Available | Yes |

| Safety Scanner | Fanuc DCS area in combination with the Sick floor scanner |

| Portable | Yes |

| Workpiece diameter (min-max) | 10mm – 300 mm |

| Maximum height of workpiece | 300 mm |

| Maximum load capacity robot arm | 70 kg |

| Maximum total weight on rotating table | 3000 kg |

| Max Number of Workpieces for Grid Plate 10-35mm | 320 |

| Max Number of Workpieces for Grid Plate 23-55mm | 220 |

| Max Number of Workpieces for Grid Plate 23-85mm | 120 |

| Max Number of Workpieces for Grid Plate 23-115mm | 82 |

| Max Number of Workpieces for Grid Plate 23-135mm | 44 |

| Max Number of Workpieces for Grid Plate 23-175mm | 28 |

| Max Number of Workpieces for Grid Plate 23-195mm | 24 |

| Max Number of Workpieces for Grid Plate 23-230mm | 18 |

| Max Number of Workpieces for Grid Plate 23-300mm | 10 |

| Capacity for Long Shafts | Yes |

| Workpiece Specific Grid Plate | Optional |

| Power | 400V |

| Dimensions (L x D x H) | 2800 x 2250 x 2220mm |

| Weight | 2800 kg |

| Weight Capacity | 70Kg |