ERKO BPS-P Busbar Processing Station

Description

ERKO BPS-P Busbar Processing Station

Manufacturer: ERKO Electro

Model: BPS-P

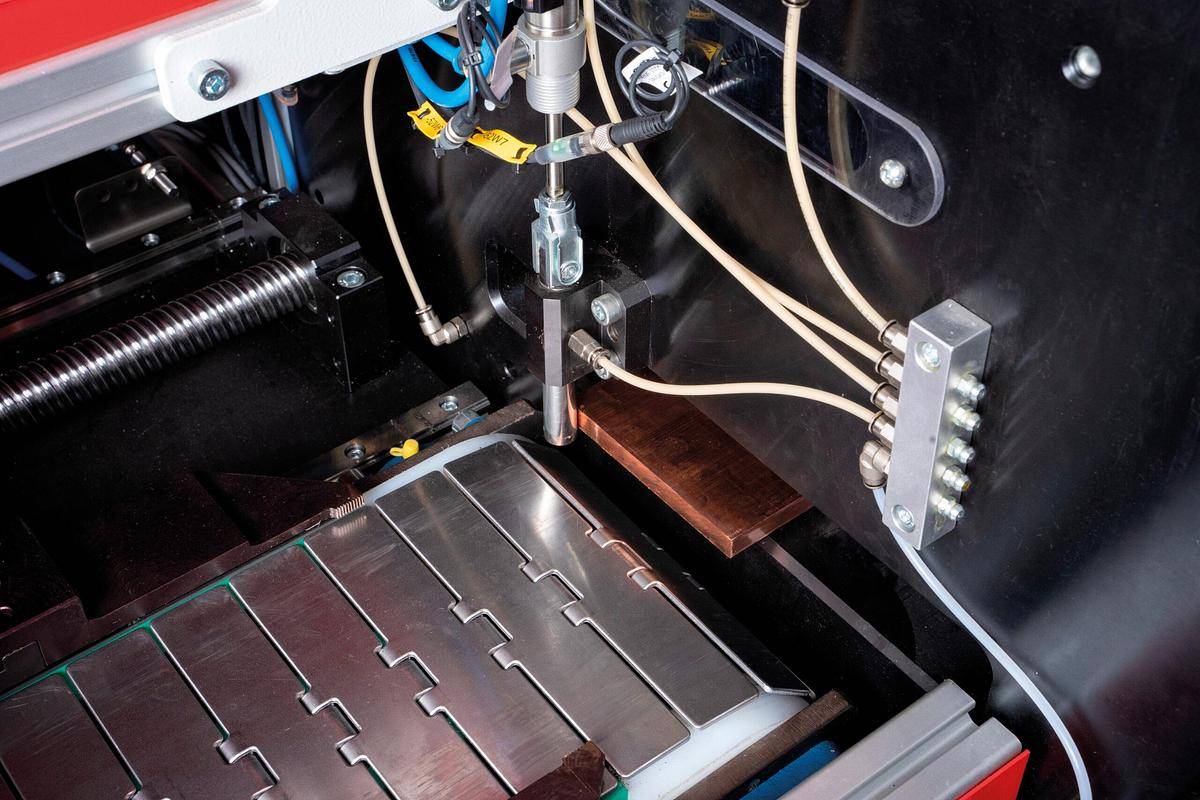

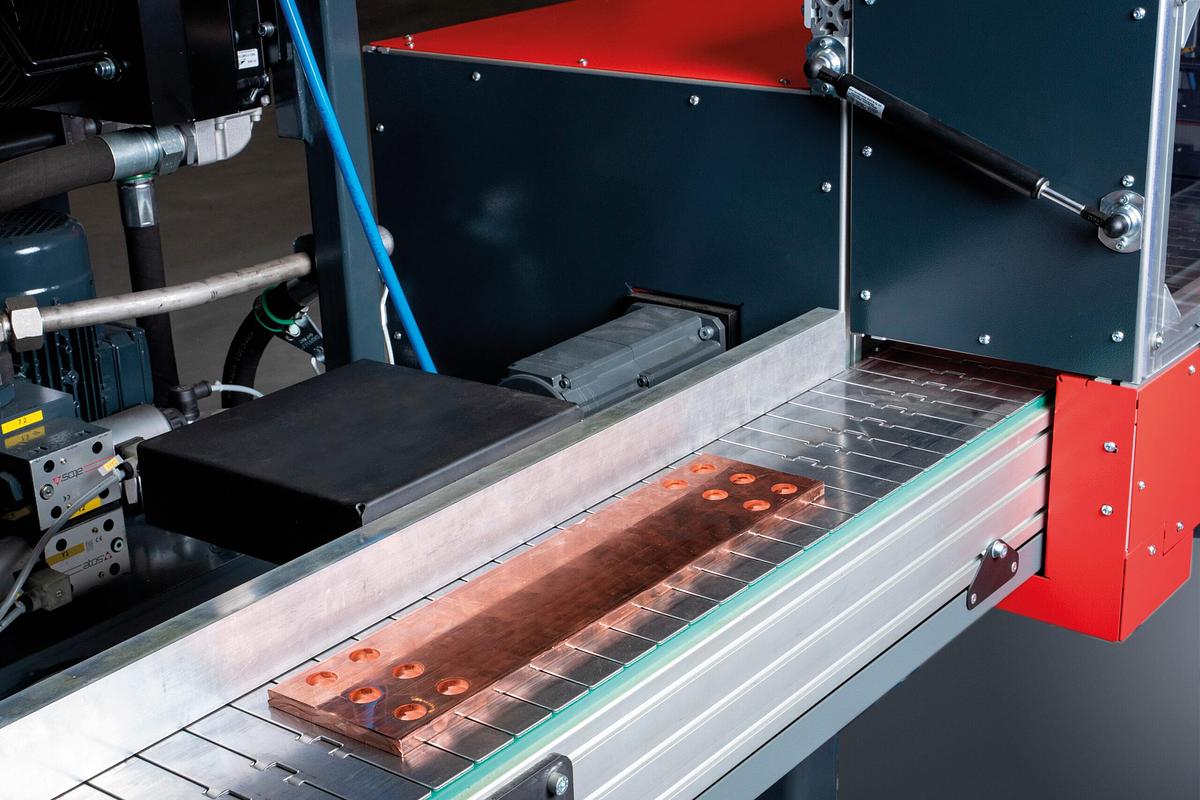

Machine Type: CNC Controlled Station for precise cutting & hole punching of Al and Cu busbars.

Description

The ERKO BPS Machines are an intelligent range of busbar processing machines designed for multi-stage and high performance processing of copper, aluminium and bimetallic busbars.

Increasing the speed of the busbar production process by up to 30% compared to the previous generation.

CNC Station for precise cutting& hole punching on Al and Cu busbars :

• busbar width from 20 to 160 mm

• busbar thickness 3 to 15 mm

• maximum length of the cut busbar: 4 metres

Why the BPS Intelligent Line?

Technological Advancement - Ability to implement complex designs

Precision & Repeatability - Compliance of the design with the final product and the current requirements

High Performance - Speed of operation and savings in time and money

Modern and Flexibility - Intuitive way of designing and intelligent support of the operator

Features

• Direct work of the machine with the innovative algorithm for designing busbars

• operator support covers designing, technology, and processed material

• application providing possibility to print the designed busbar in 2D and 3D views

• possibility of adaptation to work in the production line

• control system performing CNC functions

• designing busbars directly on the machine with a 3D visualisation and generating the developed length of a bent busbar

• equipped with a 22-inch operator’s touchscreen with the multitouch function

• dedicated to high-performance and precise serial production

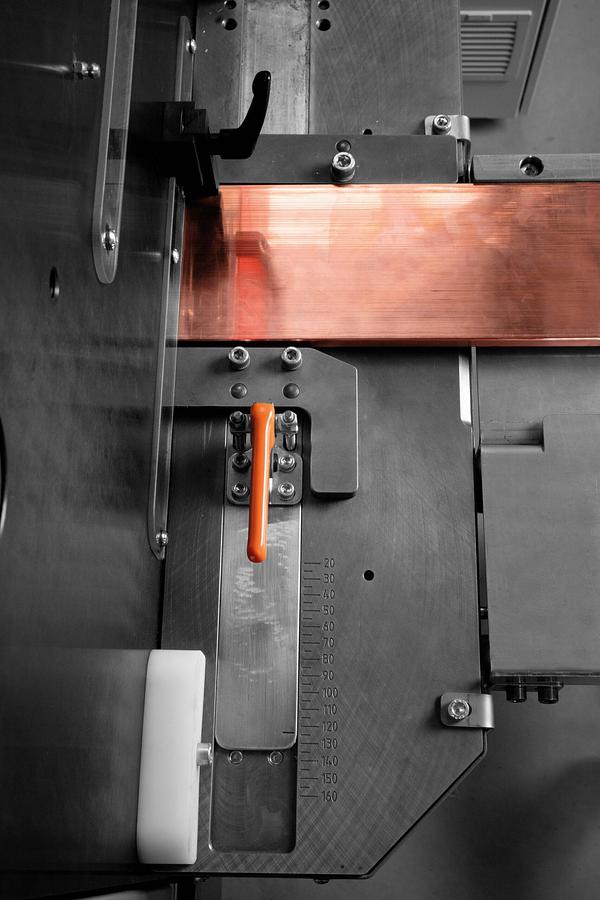

• busbar feeding ruler accuracy of the position: 0.1 mm

• movable cassette which allows installing of five punches and eliminates the need for retooling

• burr-free round, oval, and custom-designed holes punching

• minimum length of cut busbar: 25 mm

• burr-free and no surface deformation, single operation busbar cutting

• possibility of saving designs on a network drive

• possibility of using designs developed on desktop software

• possibility of extending the machine with additional machining tools (e.g. custom-made punches)

• remote software update, including material base

• it facilitates use for people with disabilities

• stable, stationary structure

• force of pressure 300 kN

Technical Specifications

Min Busbar Width: 20mm

Max Busbar Width: 160mm

Min Busbar Thickness: 3mm

Max Busbar Thickness: 15mm

Min Punching Diameter: 5.5mm

Max Punching Diameter: 21mm

Min Busbar Length: 25mm

Max Busbar Length: 4,000mm

Feeder Accuracy: 0.1mm

Pressure: 300 Bar

Electrical Connection: 3 Phase

Power: 21kW

Dimensions: 7253x3639x2000mm

Weight: 3,200kg

Specifications

| Manufacturer | ERKO |

| Model | BPS-P Busbar Processing Station |

| Condition | New |

| Stock Number | 969740 |

| Manufacturer | ERKO Electro |

| Model | BPS-P |

| Min Busbar Width | 20mm |

| Max Busbar Width | 160mm |

| Min Busbar Thickness | 3mm |

| Max Busbar Thickness | 15mm |

| Min Punching Diameter | 5.5mm |

| Max Punching Diameter | 21mm |

| Min Busbar Length | 25mm |

| Max Busbar Length | 4,000mm |

| Feeder Accuracy | 0.1mm |

| Pressure | 300 Bar |

| Electrical Connection | 3 Phase |

| Power | 21kW |

| Dimensions | 7253x3639x2000mm |

| Weight | 3,200kg |