ERKO BPS 1200 Busbar Processing Station

Description

ERKO BPS 1200 Busbar Processing Station

Manufacturer: ERKO Electro

Model: BPS 1200

Machine Type: NC Controlled Station for precise cutting, bending, hole punching of Al and Cu busbars.

Description

The ERKO BPS Machines are an intelligent range of busbar processing machines designed for multi-stage and high performance processing of copper, aluminium and bimetallic busbars.

Increasing the speed of the busbar production process by up to 30% compared to the previous generation.

Station for Al and Cu busbars precise cutting, bending, hole punching, offsetting:

• busbar width from 20 to 125 mm

• busbar thickness 5 to 12 mm

• bending angle 5° to 90°

Why the BPS Intelligent Line?

Technological Advancement - Ability to implement complex designs

Precision & Repeatability - Compliance of the design with the final product and the current requirements

High Performance - Speed of operation and savings in time and money

Modern and Flexibility - Intuitive way of designing and intelligent support of the operator

Includes

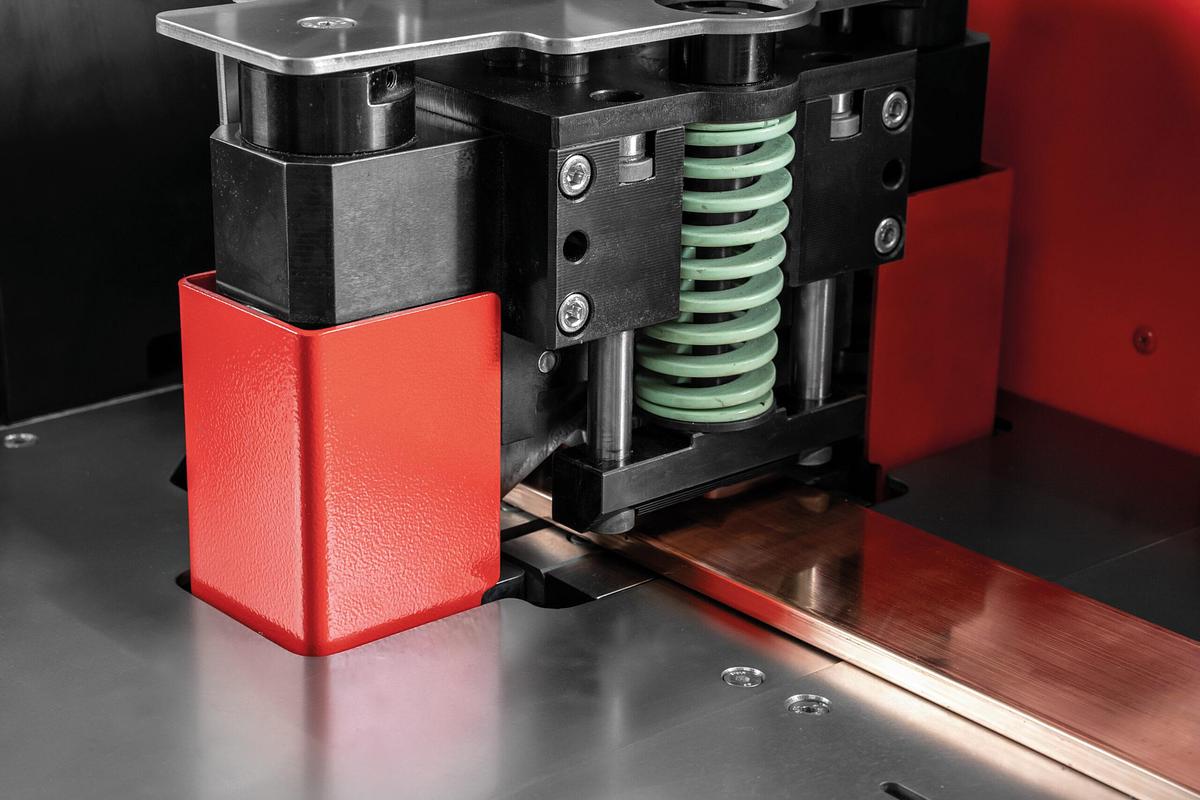

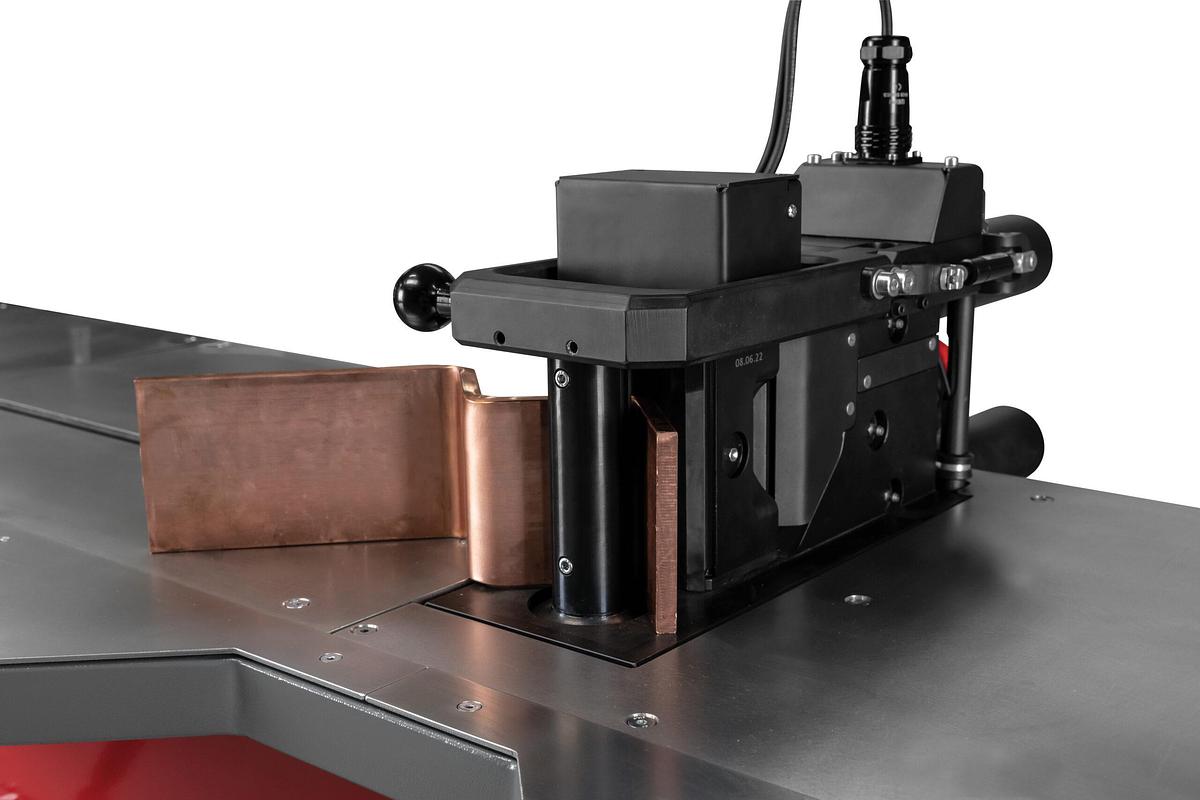

Bending Station

Punching Station

Shearing Station

Built in ElectroHydraulic Pump

Insert die for busbars offsetting

External Port

Mobile Cart

Length Stop

Insert for repeatable bending (built-in limit switch)

Measurement of length L, range 0-500 mm, precision 0,1 mm

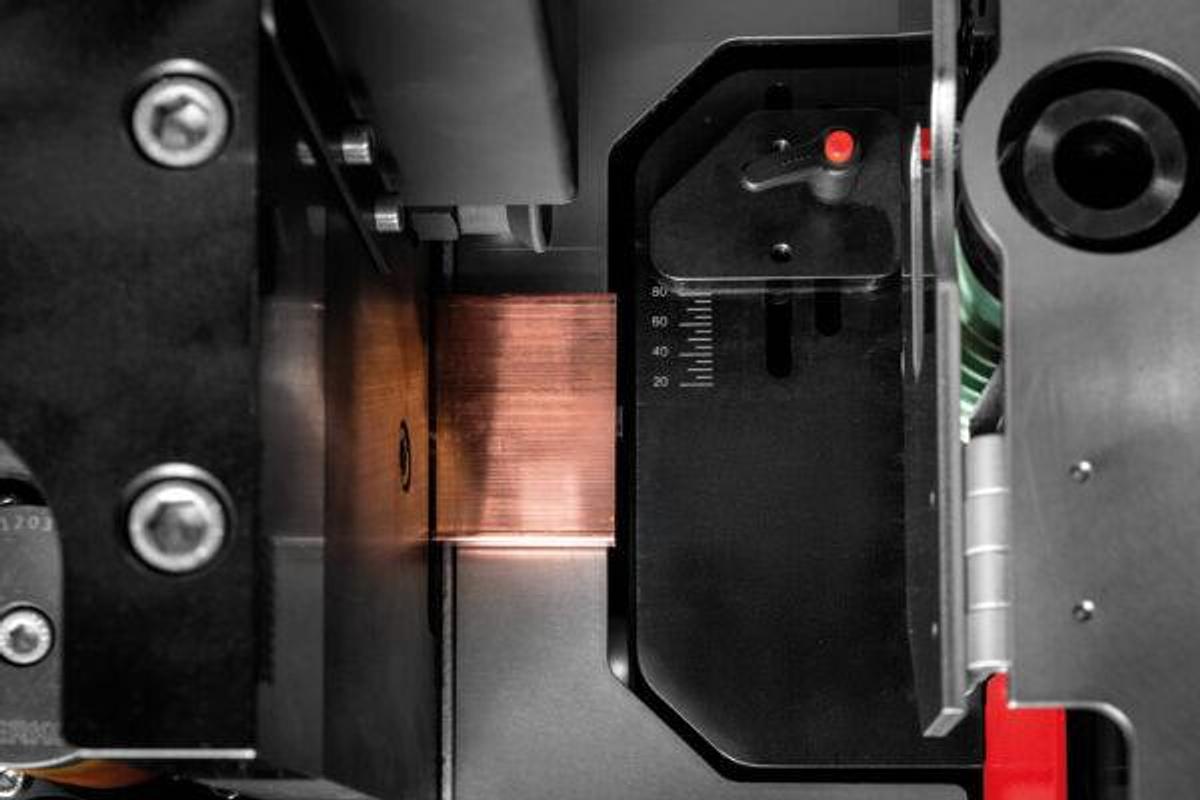

Busbar cutter

Features

• increasing the speed of the busbar production process by up to 30% compared to the previous generation

• it works with innovative software for designing busbars

• possibility to use the innovative computational algorithm

• automatic positioning of the measuring ruler during punching, bending, and cutting operations (based on procedures or previously entered data)

• measuring ruler position accuracy 0.1mm for cutting and punching of processed busbars (up to 2,000 mm) and bending (up to 1,600 mm)

• possibility of bending in an “L” shape for busbars up to 10 mm thick at a distance of 40 mm from the edge

• possibility of bending in a “C” shape for busbars up to 10 mm thick at a distance of 45 mm from the edge

• possibility of bending in a “Z” shape for busbars up to 10 mm thick at a distance 40 mm from the edge and between the bends the bends

• bending angle accuracy ± 0 2° with adjustment for busbar elasticity

• guillotine can be hidden under the worktop surface

• automatic controlled press of the cut busbar

• minimum length of cut busbar: 30 mm

• burr-free and no surface deformation busbar cutting

• a movable cassette which allows installing of four punches and eliminates the need for retooling

• burr-free round and oval holes punching

• possibility of saving and recalling busbar processing procedures

• built-in reliable and efficient hydraulic drive

• additional connections for other tools offered by ERKO (hydraulic hose with a PM quick coupler)

• maintained mobility of the machine

• possibility of remote diagnostics

Technical Specification

Min Busbar Width: 20mm

Max Busbar Width: 125mm

Min Busbar Thickness: 5mm

Max Busbar Thickness: 12mm

Min Punching Diameter: 5.5mm

Max Punching Diameter: 21mm

Max Bending Angle: 90 Deg

Pressure: 630 Bar

Electrical Connection: 3 Phase

Motor Power: 2kW

Dimensions: 3800x2000x1700mm

Weight: 650kg

Specifications

| Manufacturer | ERKO |

| Model | BPS 1200 Busbar Processing Station |

| Condition | New |

| Stock Number | 969739 |

| Manufacturer | ERKO Electro |

| Model | BPS 1200 |

| Min Busbar Width | 20mm |

| Max Busbar Width | 125mm |

| Min Busbar Thickness | 5mm |

| Max Busbar Thickness | 12mm |

| Min Punching Diameter | 5.5mm |

| Max Punching Diameter | 21mm |

| Max Bending Angle | 90 Deg |

| Pressure | 630 Bar |

| Electrical Connection | 3 Phase |

| Motor Power | 2kW |

| Dimensions | 3800x2000x1700mm |

| Weight | 650kg |