Uzma CAP-E 1240 Hydraulic Pressbrake

Description

UZMA CAP-E 1240 Hydraulic Pressbrake

Manufacturer: UZMA Makina

Model: CAP-E 1240

Machine Type: CNC Controlled Hydraulic Pressbrake

Capacity: 1270mm x 40T

Control: Cybelec

About UZMA Makina (Turkey)

With the accumulation of our experience in metal working machinery sector which started in 1996, we established UZMA brand in 2005. In 2007, not only UZMA brand became a registered trademark but also in 2013 we received the ISO 9001 :2008 certificate. Today with nearly 25 years of experience in the machinery industry, UZMA is one of the fastest growing companies and brand names in the world market for Metal Working Machinery with his own production and OEM products.

UZMA Press Brakes and Shears has monoblock steel construction frame and designed to be reliable, durable and precise. Designs, that are carried out on computer including 3D software, support for drawing and strength analysis. For all UZMA products, precise machining with CNC machining center and/or CNC lathes are accompanied with detailed quality control and designed to produce quality repeatable precision works. UZMA has a big production range from full CNC machines to simple mechanical machines for different customer budgets and usage areas. Equipment on the machines are worldwide known brand names like Bosch-Rexroth, Hoerbiger, Givi Misure, Heidenhain, Wila, Delem, Cybelec, ESA, Siemens, Schneider, Mitsubishi, etc.

The target of UZMA is to keep the name as a world wide brand name with high quality and affordable prices, we believe in customer satisfaction and after sale service.

Our aim in the world market is to continue to be in a distinguished place and to stay united with the quality.

We know that we can grow only together with our partners and customers, therefore our first target is customer satisfaction.

Machine Description

UZMA synchro CNC press brakes have accurate positioning and repeatability performance, achieved by synchronizing the hydraulic cylinders with proportional valves and optical linear scales. At CAP series press brakes, full electronic synchronization with proportional valve technology assuring maximum bend accuracy and repeatability through constant monitoring and correction of beam parallelism by a CNC system. UZMA CAP series synchro CNC press brakes are produced in 4 sub-series in different configurations, B-Series (Basic), E-Series (Economic), S-Series (Standard) and A-Series (Advanced). The CAP series press brakes are available from simple basic series to high

equipped advanced series which can be configurated up to eleven axis. UZMA synchro CNC press brakes are calculating and performing facilities after inputting data like material, thickness, bending length, etc., to the CNC control unit. Calibration of cylinder's axes and back gauge, maintained by automatic indexing at the start of CAP series press brakes.

General Features

• Body and upper beam are made of steel constructions.

• All UZMA machines are designed by SOLID WORKS 3D programming and made with enhanced ST44-ST52

quality steel using the latest technology.

• This machine has rigid upper beam and runs with high bending precision.

• High quality and repetitive bendings are obtained by using synchronized cylinders and valves.

• Cylinders, processed from solid full material.

• Chrome coated cylinders are machined with high precision and pistons are specially hardened.

• Worldwide and well-known brands such as HOERBIEGER, BOSCH-REXROTH, SCHNEIDER, SIEMENS hydraulic

and electrical systems are used on UZMA machines.

• Maximum hydraulic pressure protection by safety valve.

• Electronic overload protection system.

• Optical linear scales are sensitive up to ± 0,01 mm.

• Synchronized working cylinders will give you the best bending result with perfect repeatability

ratio.

Standard Accessories

- Y1-Y2-X axis

- Available with Cybelec CNC touch screen control units

- Pendant control panel for easy operation

- X-axis back gauge

- European (promecam) quick release top tool clamping system

- Full set of top & bottom Eurostyle Tooling

- Back light barrier

- Switched side protection panels for safety

- European hydraulic system

- European electrical system

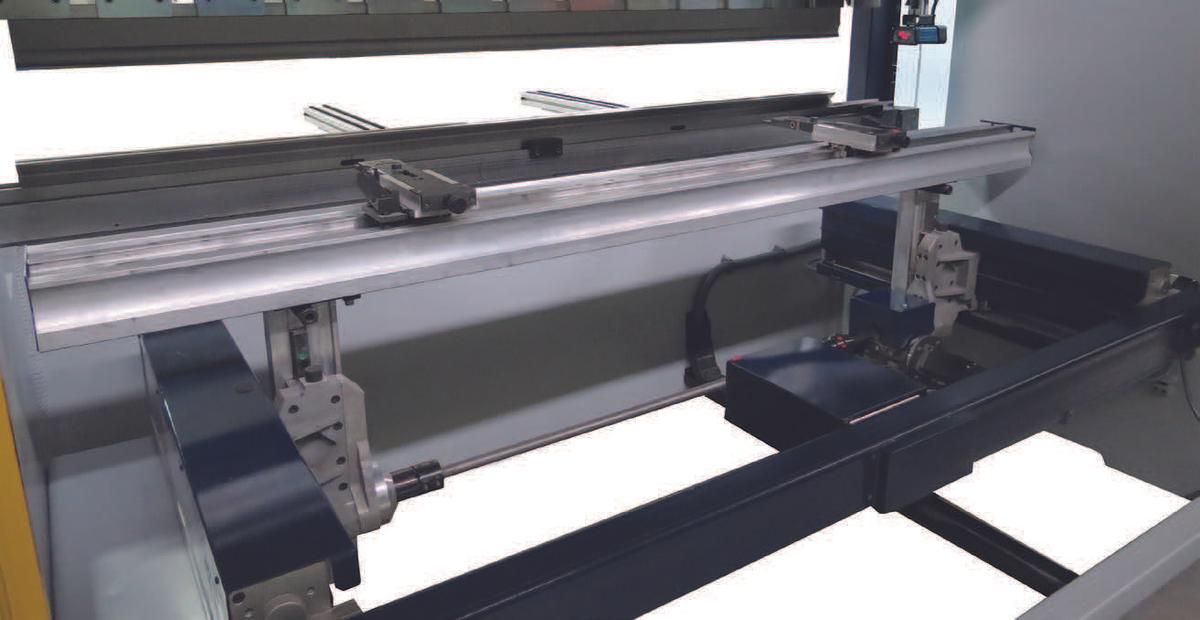

- Linear sliding front support arms

- High stroke, high daylight and high speed

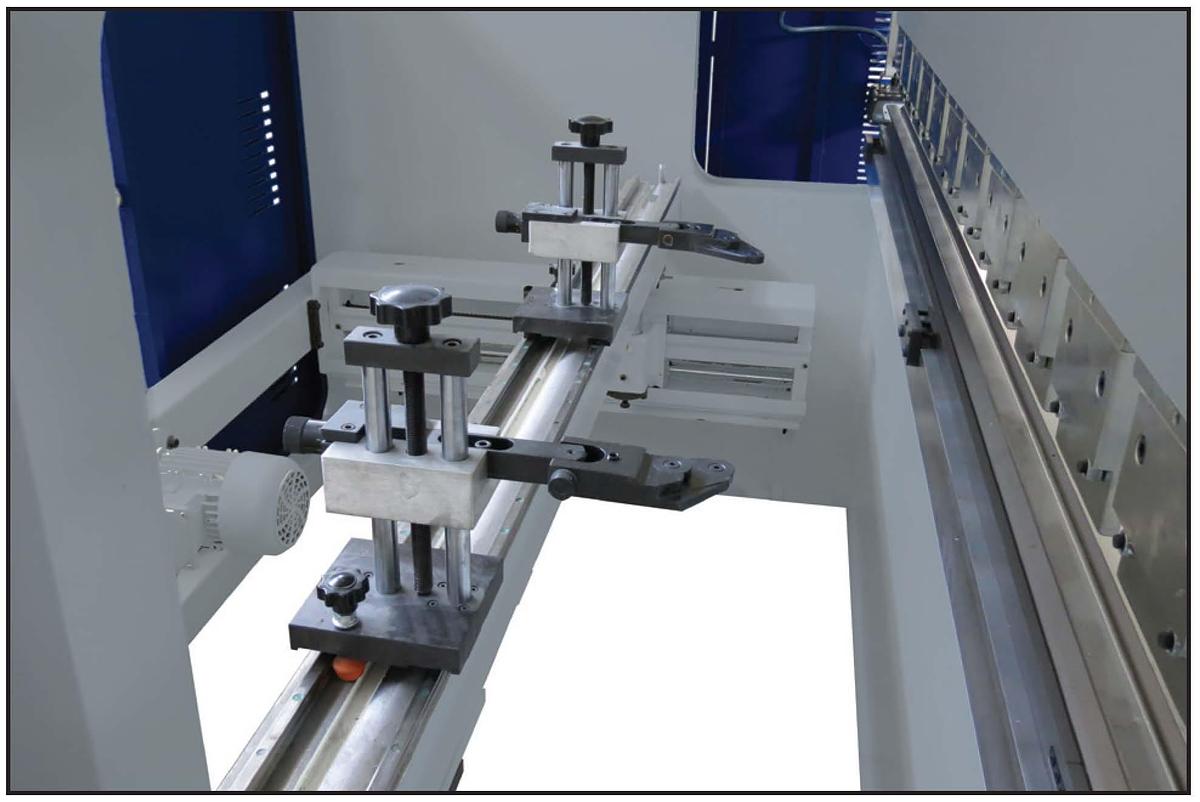

Back Gauge

Back Gauge Type: X single axis back gauge

Back Gauge Range: 800mm

Our heavy duty back gauge is designed according to the size and tonnage of the machine. X axis (forward/reverse) operates on linear ball bearings and ball screw. Manual R axis (up & down) adjustment is made easily with handle from the top of fingers.

Optional X - R back gauge is available on request.

Technical Specifications

Bending Power: 40T

Bending Length: 1270mm

Distance Between Side Frames: 1050mm

Stroke: 170mm

Daylight: 387mm

Throat Depth: 350mm

Table Height: 850mm

Approach Speed: 140mm/s

Working Speed: 17mm/s

Return Speed: 170mm/s

Motor Power: 5.5kW

Oil Tank: 80L

X Axis(Back Gauge) Travel: 800mm

X Axis(Back Gauge) Speed: 230mm/s

Machine Dimensions (LxWxH): 2150 x 1650 x 2300mm

Machine Weight: 3,050kg

Optional Extras

Manual Crowning

CNC Motorised Crowning

Extra Tooling

X/R Back Gauge

Z Axis Back Gauge

4 Axis Back Gauge

Specifications

| Manufacturer | Uzma |

| Model | CAP-E 1240 Hydraulic Pressbrake |

| Condition | New |

| Stock Number | 969553 |

| Manufacturer | UZMA Makina |

| Model | CAP-E 1240 |

| Machine Type | CNC Controlled Hydraulic Pressbrake |

| Capacity | 1270mm x 40T |

| Control | Cybelec |

| Back Gauge Range | 800mm |

| Bending Power | 40T |

| Bending Length | 1270mm |

| Distance Between Side Frames | 1050mm |

| Stroke | 170mm |

| Daylight | 387mm |

| Throat Depth | 350mm |

| Table Height | 850mm |

| Approach Speed | 140mm/s |

| Working Speed | 17mm/s |

| Return Speed | 170mm/s |

| Motor Power | 5.5kW |

| Oil Tank | 80L |

| X Axis(Back Gauge) Travel | 800mm |

| X Axis(Back Gauge) Speed | 230mm/s |

| Machine Weight | 3,050kg |