Hidrogarne PMF-2L 200 H-Type Mechanical Press

Description

Hidrogarne PMF-2L 200 H-Type Mechanical Press

Manufacturer: Hidrogarne

Model: PMF-2L 200

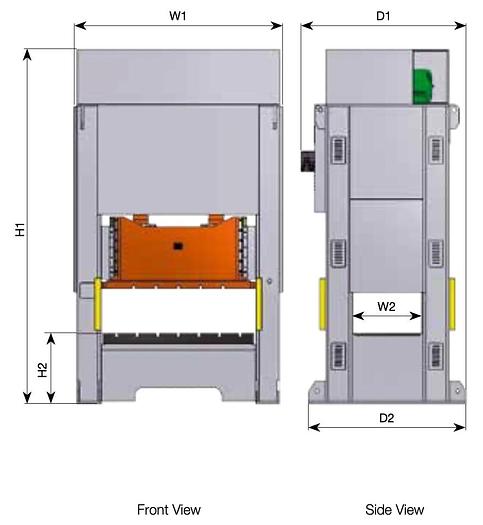

Machine Type: H-Type Mechanical Presses with Double Connecting Rod and Fixed Stroke

Series: PMF-2L Mechanical Presses

Power: 200T

Description

The PMF series double-column mechanical presses are suitable for a wide variety of applications in industries such as automotive, aerospace, railway, and many others related to metal forming. These are double reduction presses with one or two connecting rods.

They are constructed from S355JR steel, stabilized, and machined at the end of the welding process to ensure perfect parallelism and precision. Designed and calculated using finite element software, we consistently guarantee our high standards of precision and quality.

The connecting rod is made of high-strength forged steel with high-performance alloyed bushings.

To ensure perfect maintenance and operation, our entire range is equipped with centralized automatic lubrication with a programmable progressive system.

Designed with a complex system of counter-rotating eccentric gears that allows for a double speed reduction and long strokes. High energy is also achieved at very low nominal speeds, suitable for deep drawing operations.

The dimensions of the heights of the prismatic guides and sliding surfaces are to offer maximum rigidity under high demands, limiting the deformation of the working surfaces to minimal values.

The ram has 6 prismatic guides. They are double reduction with double connecting rods, fixed stroke, and large tables.

Available with power ranging from 300 to 630 tons.

Overload and Compensation

It is equipped with an overload protection unit that protects the machine components and the installed tools. A safety valve releases the oil from the chamber when, for any reason, the set value, which is higher than the nominal load, is reached.

For effective balancing of the ram and dies, compensation is provided by two pneumatic cylinders

Clutch - Brake

The clutch-brake is electro-pneumatically operated, equipped with a double-body safety solenoid valve and cross-flow.

The pneumatic system includes a compensation tank, regulator-lubricator filter, control pressure switch, and safety valve.

Electrical Installation and Safety

The electrical panel includes a selector switch that allows you to choose the type of work to be performed in manual, semi-automatic, or automatic mode. The electrical and pneumatic operations are redundant and self-controlled. They include an additional PLC for operation and safety.

The operation is carried out using a two-hand push button and a low-voltage electric pedal.

To ensure safety, they include practicable side guards with category IV photoelectric barriers located on the sides of the working area.

Features

Pneumatic clutch

Dual safety valve

Two-hand control

Electric pedal control

Automatic centralized lubrication

Oil-bath gears

Automatic ram adjustment

Shut height indicator

Mechanical cam limit sensor

Magnetic cam limit sensor

Speed variator

Programmable PLC (automaton)

Touchscreen display

Front and rear photoelectric barriers

Hydraulic overload protector

Safety prop

Articulated hanging panel

Pneumatic balancers

Anti-vibration pads

Optional Accessories

Speed variator.

Pneumatic or hydraulic ejector or cushion.

Auxiliary lower table.

Quick die change system.

Digital force control.

Technical Specifications

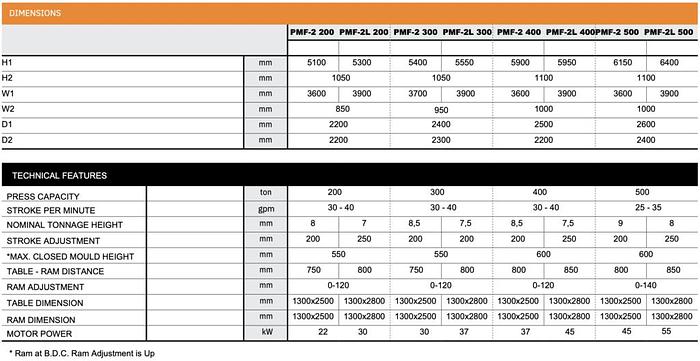

Press Capacity: 200T

Strokes Per Min: 30-40gpm

Nominal Tonnage Height: 7mm

Stroke Adjustment: 250mm

Max Closed Mould Height: 550mm

Table to Ram Distance: 800mm

Ram Adjustment: 0-120mm

Table Dimensions: 1300 x 2800mm

Ram Dimensions: 1300 x 2800mm

Motor Power: 30kW

Specifications

| Manufacturer | Hidrogarne |

| Model | PMF-2L 200 H-Type Mechanical Press |

| Condition | New |

| Stock Number | 969523 |

| Manufacturer | Hidrogarne |

| Model | PMF-2L 200 |

| Series | PMF-2L Mechanical Presses |

| Power | 200T |

| Press Capacity | 200T |

| Strokes Per Min | 30-40gpm |

| Nominal Tonnage Height | 7mm |

| Stroke Adjustment | 250mm |

| Max Closed Mould Height | 550mm |

| Table to Ram Distance | 800mm |

| Ram Adjustment | 0-120mm |

| Table Dimensions | 1300 x 2800mm |

| Ram Dimensions | 1300 x 2800mm |

| Motor Power | 30kW |