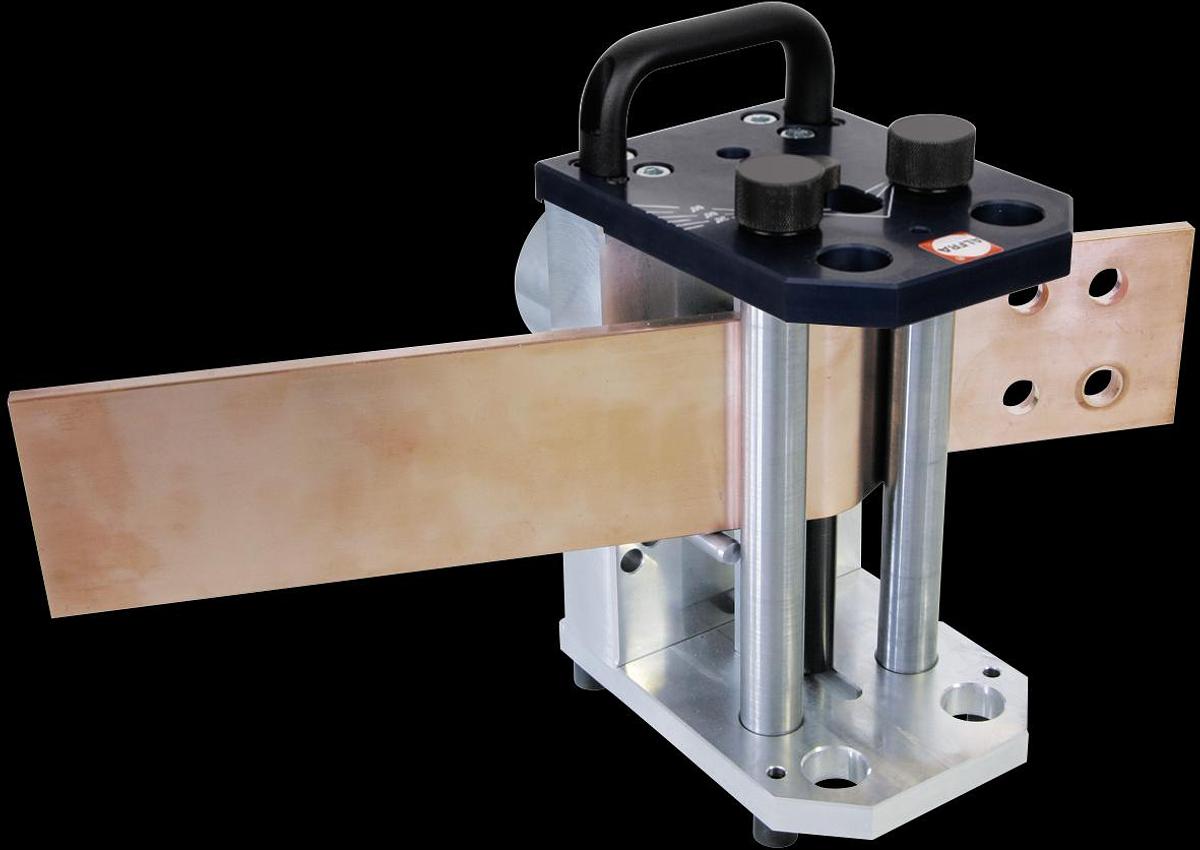

Alfra GmbH BS160 Busbar Bending and Hole Punching Machine

Description

💪 ALFRA BS 160 Busbar Bending & Hole Punching Machine – High-Precision, Heavy-Duty Power for Copper & Aluminum

Looking to streamline your busbar fabrication process? The ALFRA BS 160 is your all-in-one solution for busbar bending and hole punching—delivering unmatched accuracy, speed, and ease of use for modern electrical workshops and switchgear production.

Product No.: 03258

🔧 Product Overview – ALFRA BS 160

The ALFRA BS 160 combines busbar hole punching and precise angle bending in a single, rugged device. Built for industrial performance, it’s designed to handle copper and aluminum busbars up to 160mm wide and 12mm thick, making it ideal for panel builders, OEMs, and MRO teams.

✅ Key Features of the ALFRA BS 160 Busbar Machine

- Dual-Function Design: Combines busbar hole punching and angle bending into one powerful tool

- High Capacity: Supports busbars up to 160 mm wide and 12 mm thick

- Hydraulic Operation: Powerful hydraulic system ensures effortless processing

- Precision Engineering: Accurate bend angles up to 90° and clean, round holes without burrs

- Heavy-Duty Construction: German-made for long service life and consistent performance

- Mobile or Stationary: Compact footprint for workbench use or mobile onsite jobs

📐 Technical Specifications

Bending

Bending Cu max: 160 x 12 mm

Bending up to: 92°

Smallest leg length: 50 mm

Smallest U-bend: 160 mm

Smallest Z-bend: 55 mm (depending on material thickness)

Punching

Punching Cu: 6.6 - 21.5 mm also longitudinal hole up to max. L = 21 mm

Material thickness Cu max: 12 mm

Material width up to: 160 mm central

Dimensions L x W x H: 390 x 150 x 330 mm

Weight: 20 kg

** Requires Electro-Hydraulic Pump for use. Not included in supply. Options available can be found here: Alfra Hydraulic Pumps

🛠️ Perfect For

- Electrical panel and switchboard manufacturers

- Industrial maintenance teams

- Power distribution installations

- Electrical contractors and fabricators

- OEMs and system integrators

📦 What’s Included

- ALFRA BS 160 Busbar Unit

- Bending Die R=11mm for busbars 9-12mm

- User Manual & Safety Guide

- Full Manufacturer Warranty

🚀 Why Choose the ALFRA BS 160 Busbar Bending & Punching Device?

- 🕒 Increase Production Speed – Dual functions save time on setup and processing

- 🔧 No Rework Required – Clean cuts and accurate bends reduce scrap and finish work

- 🔌 No Power Required (Optional) – Operate manually or upgrade to hydraulic power unit

- 🛡️ Reliable & Durable – Backed by ALFRA’s global reputation for quality

📦 Order the ALFRA BS 160 Today – In Stock & Ready for Dispatch

- 🌍 Fast Delivery Across Ireland & UK

- 💬 Support & After-Sales Assistance

- Busbar bending and punching machine

- ALFRA BS 160 for sale

- Copper busbar processing machine

- Electrical panel fabrication tools

- Busbar hole punching device

- ALFRA hydraulic busbar tools

- Busbar bender with punch combo

Specifications

| Manufacturer | Alfra GmbH |

| Model | BS160 Busbar Bending and Hole Punching Machine |

| Condition | New |

| Stock Number | 968936 |

| Product No. | 03258 |

| Bending Cu max | 160 x 12 mm |

| Bending up to | 92° |

| Smallest leg length | 50 mm |

| Smallest U-bend | 160 mm |

| Material thickness Cu max | 12 mm |

| Material width up to | 160 mm central |

| Weight | 20 kg |

| [https | //www.usedmachinetoolsireland.com/new/alfra-gmbh/alfra-hydraulic-pumps] |