Alfra GmbH BS120 Busbar Bending, Punching Machine

Description

🛠️ Alfra BS120 Busbar Bending & Punching Machine – Heavy-Duty Precision Tool for Electrical Fabrication

Buy the Alfra BS120 Busbar Machine – Bend and punch copper and aluminum busbars with speed, accuracy, and efficiency. Ideal for electrical contractors, panel builders, and switchgear manufacturers.

Product No: 03912

🔍 Product Overview

The Alfra BS120 Busbar Bending & Punching Machine is a powerful 2-in-1 solution designed for professional busbar fabrication. With its robust hydraulic system and compact design, this machine is engineered to handle demanding industrial tasks with ease.

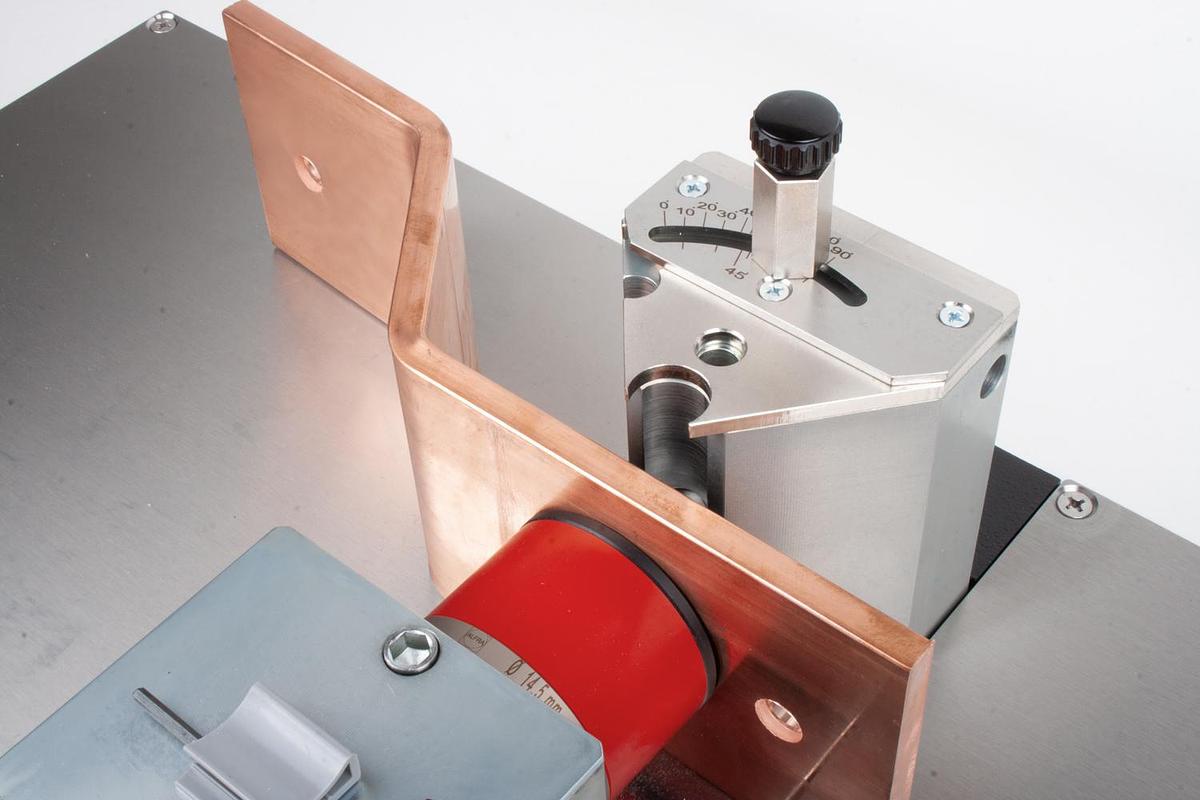

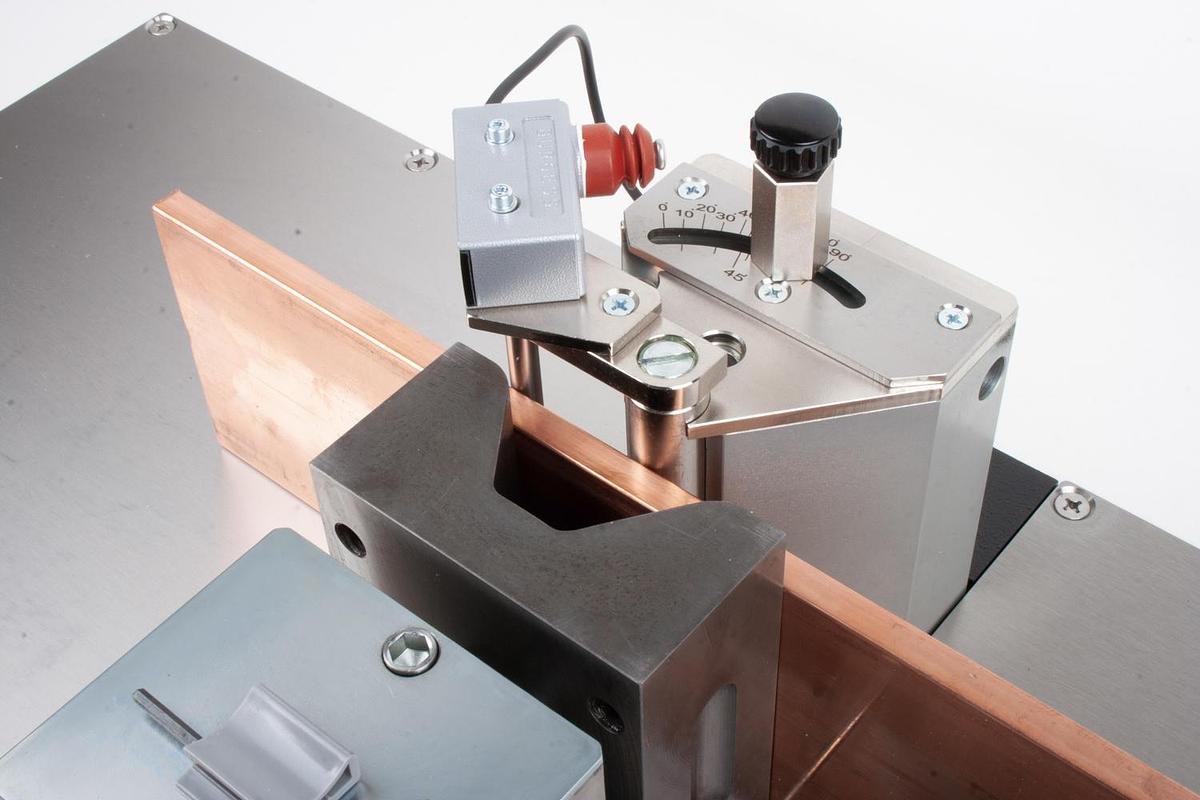

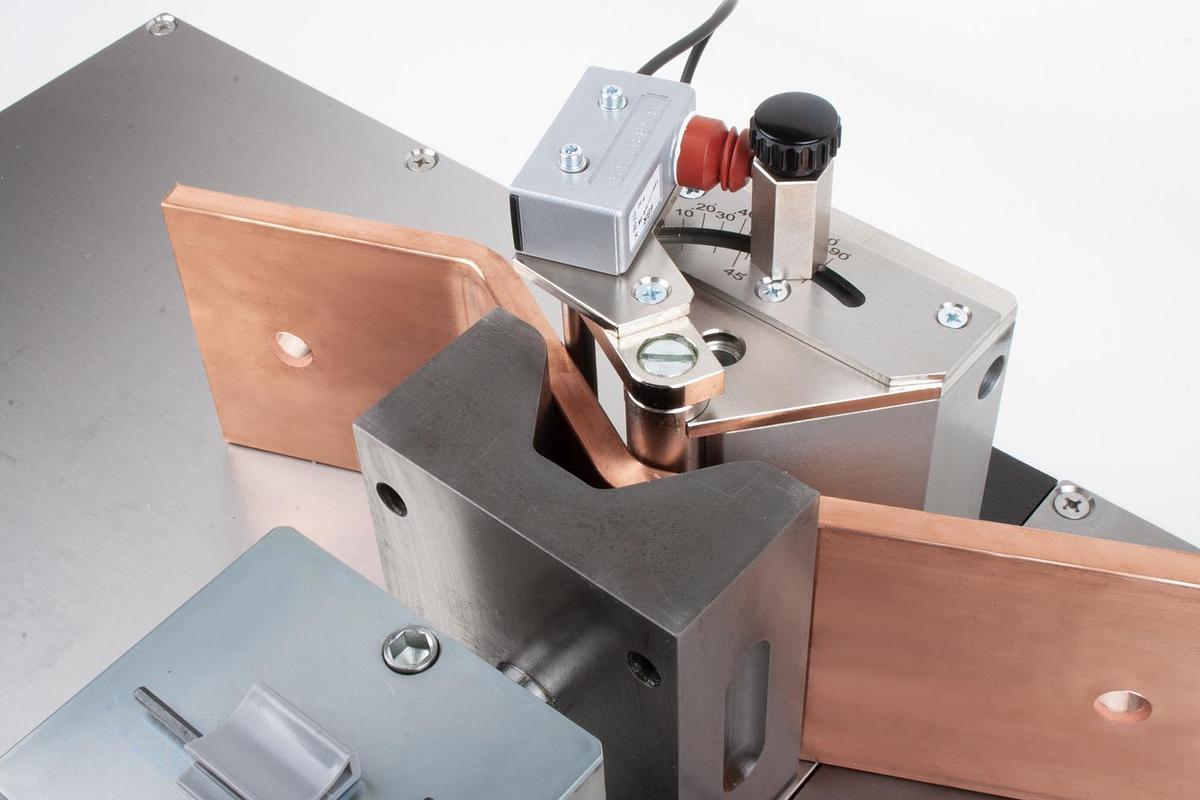

Where electricity flows, millimeters matter. Alfra's busbar bending and hole punching machine ensures that the conductive copper busbars fit precisely into the switch cabinet - thanks to an electrical angle reader, bending die and length stop. When the switch is set to 'Bending', the bending die only has to be inserted into the hydraulic piston. The desired angle is fixed by means of a set screw. The universal working cylinder is bending conductor rails with the dimensions 120 mm X 12 mm. One device, two functions: When the switch is set to 'Punch', the BS120 punches holes with a diameter between 6.6 mm and 21.5 mm or oblong holes, depending on the used hole puncher.

✅ Key Features of the Alfra BS120 Busbar Machine

- Dual Functionality: Combine busbar punching and bending in one space-saving machine

- High Capacity: Processes busbars up to 120mm wide and 12mm thick

- Hydraulic Power: Smooth, low-effort operation with precise results

- Fast Setup: Quick-change tooling for minimal downtime

- Adjustable Bending Angles: Accurate angle settings up to 90°

- Durable German Engineering: Built for consistent performance in industrial environments

📐 Technical Specifications

Bending

Bending Cu max: 120 x 12 mm

Bending up to: more than 90°

Smallest leg length: 50 mm

Smallest U-bend: 100 mm

Smallest Z-bend: 72 mm (depending on material thickness)

The values stated are based on copper rails 120 x 10 mm

Punching

Punching Cu: 6.6 - 21.5 mm also longitudinal hole up to max. L = 21 mm

Material thickness Cu max: 12 mm

Material width up to: 110 mm central

External dimensions L x W x H: 700 x 410 x 410 mm

Weight: 60 kg

🔧 Applications

- Electrical Panel Building

- Switchgear Fabrication

- Industrial Maintenance

- Power Distribution Projects

- Busbar Processing Workshops

📦 What’s Included

- Alfra BS120 Base Unit

- Electrohydraulic Pump AHP M1 (03857)

- Foot Switch with Safety Function (03862.NG)

- Electrical Angle Measurer R10 (03201.NG)

- Bending Die R10 (03202.L)

- Length Stop (03203)

- Instruction Manual

- Manufacturer Warranty

🛒 Why Buy the Alfra BS120 Busbar Punching & Bending Machine?

- Increases Productivity: Complete bending and punching in seconds

- Reduces Manual Labor: Efficient hydraulic operation

- Space-Saving Design: Ideal for workshops with limited space

- Trusted Brand: Alfra is a leader in precision metalworking tools

🚚 Order Now – Available for Immediate Delivery

- ✔️ In stock – limited units available

- 🌍 Fast Irish & UK Shipping

- 🧰 Installation support and training available in Ireland

- Busbar punching and bending machine

- Alfra BS120 for sale

- Buy busbar fabrication machine

- CNC busbar machine Ireland/UK

- Copper busbar bending tool

- Industrial electrical fabrication tools

Specifications

| Manufacturer | Alfra GmbH |

| Model | BS120 Busbar Bending, Punching Machine |

| Condition | New |

| Stock Number | 968934 |

| Product ID | 03912 |

| Bending Bending Cu max | 120 x 12 mm |

| Bending up to | more than 90° |

| Smallest leg length | 50 mm |

| Smallest U-bend | 100 mm |

| Material thickness Cu max | 12 mm |

| Material width up to | 110 mm central |

| Weight | 60 kg |